Fe Mirror

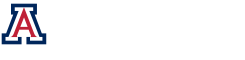

(Left) Nomarski Differential Interference Contrast (DIC) micrograph of the surface of an iron mirror approximately seven months (201 days) after I polished it. The blue bars in the lower right corner of the image are 20 ?m (787 ?inch) apart, so this micrograph will be at a magnification of ~500× on typical computer monitors. Although many scratches are quite apparent in the micrograph, this mirror produces a very nice image, showing that what scientists consider to be an “optical quality” surface is not required.

Since I live in the Sonoran Desert, to somewhat simulate the humidity of Flanders, after polishing I placed this mirror on a window sill in a bathroom at home along with a digital hygrometer. The hygrometer showed the mirror was exposed to ~40% relative humidity for ~2 hours/day, and much less than that the rest of the time. The black-appearing blotches that cover approximately 16% of the surface are Fe2O3 (rust) patches. At this rate of formation, the entire surface would be covered by an opaque coating of rust in 3½ years. In Flanders, where the 24-hour, year-round humidity averages above 60%, the rate of rusting would be even faster.

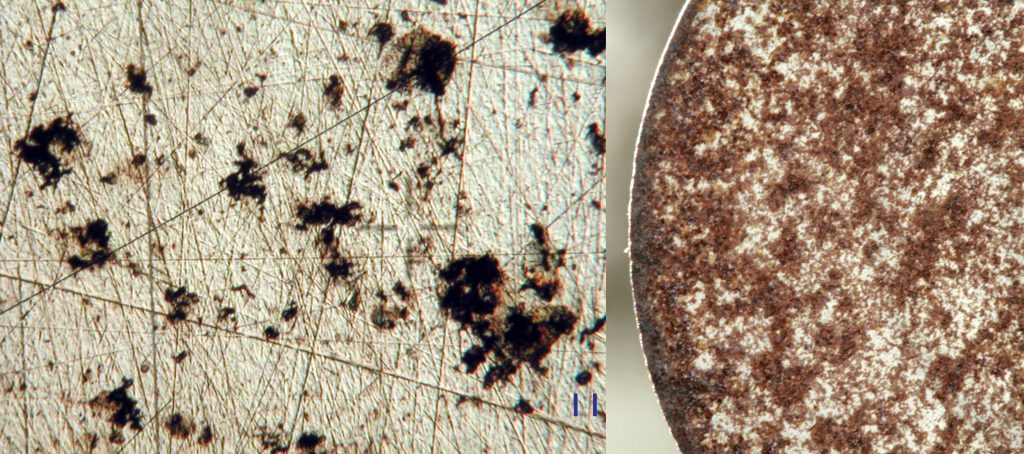

(Right) Photograph of the same 2″-dia. (5.0 cm) iron mirror after 3½ years (3 yr., 6 mo., 9 days). As can be seen, roughly 80% of the surface is now covered by rust, consistent with the initial rate of formation determined from the micrograph at the left, taken seven months after polishing.

A detailed description for making large, bright, concave, ferrous, steel mirrors is in a manuscript known to date from no later than 1372 (i.e. a half-century before van Eyck). However, other metals that also might have been used for concave mirrors in the Renaissance (brass, bronze, silver, lead, tin, etc.) form opaque oxides or sulfides as well. Although only minor periodic polishing would have been required at the time to maintain the imaging qualities of any of them, as the photograph at the right shows, the subsequent 600 years of oxidation means any such metal objects in museum collections today would be so degraded as likely to be unrecognizable as mirrors unless the museum staff had an understanding of the properties of materials.