Optical assembly

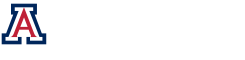

For X-ray telescopes, it is necessary to assemble many low-stiffness mirrors with sub-micron alignment precision while minimizing deformation of the mirror surface yet providing sufficient strength to survive launch into space. This results in a challenging tradeoff between accuracy and strength. Kinematic approaches enable accuracy but with insufficient strength, whereas over-constrained approaches typically limit accuracy but provide high strength and stiffness.

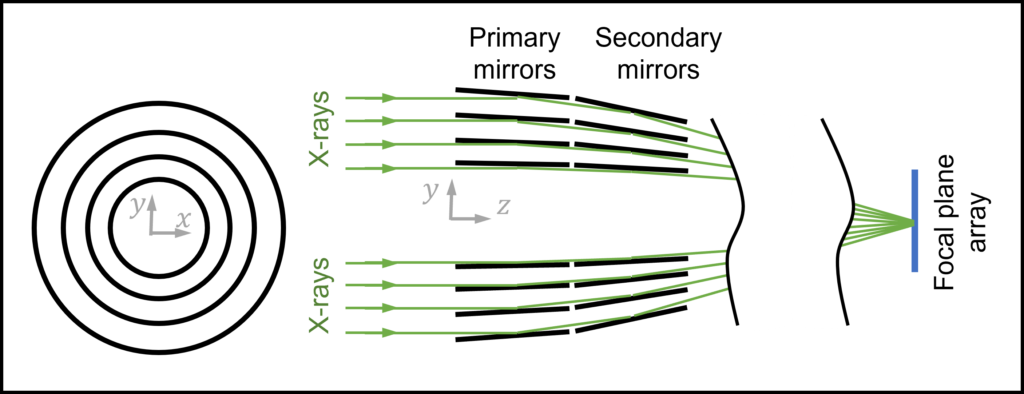

We are developing new techniques for assembling mirrors with sufficient strength for launch and accuracy for science. To do this, we are fabricating specialized compact and lightweight spacers that can be adjusted over microns of range and with nanometer resolution after assembly.

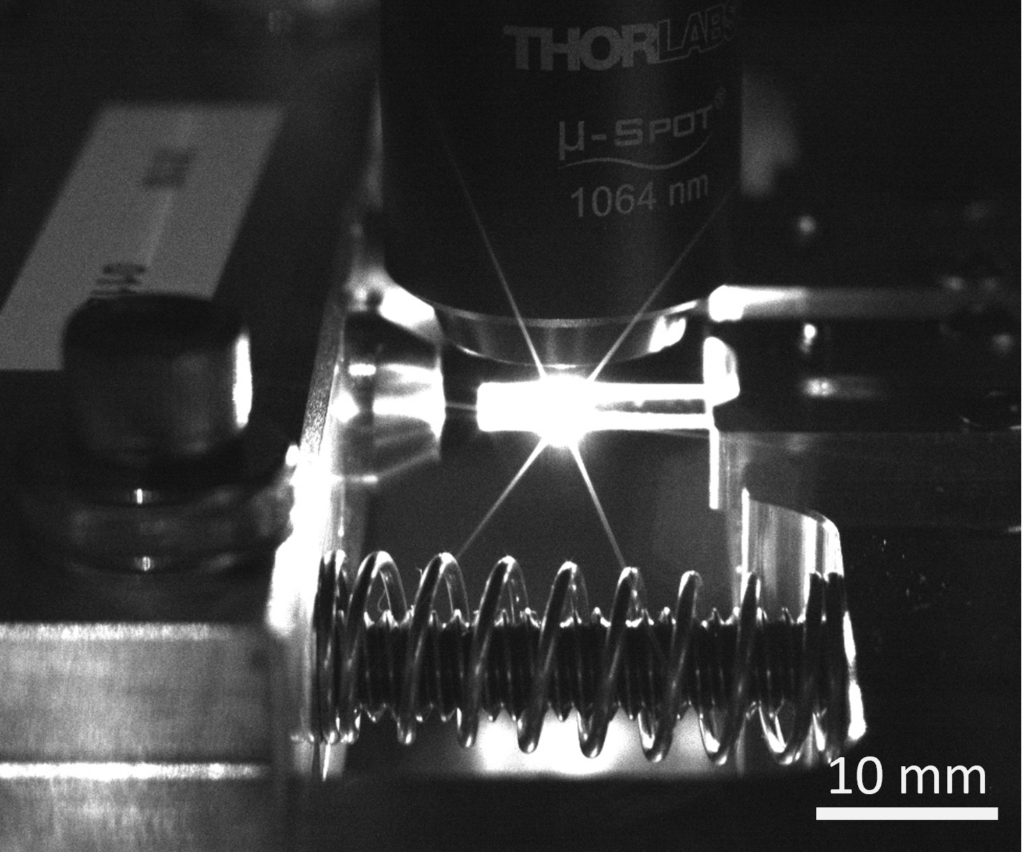

We can adjust spacer length using ultrashort pulsed (USP) laser-generated strain. The intense laser pulses result in nonlinear absorption even in transparent materials like glass, and cause strain to develop through various mechanisms including rapid heating and quenching. We are investigating the range, resolution, and stability achievable through this method.

Publications

B. D. Chalifoux, I. J. Arnold, K. A. Laverty, “Ultrafast laser strain generation for nanometer-precision alignment of optical components,” Proceedings of SPIE, Vol. 11816, p. 1181607 (2021).