Optomechanical Resonator Modelling

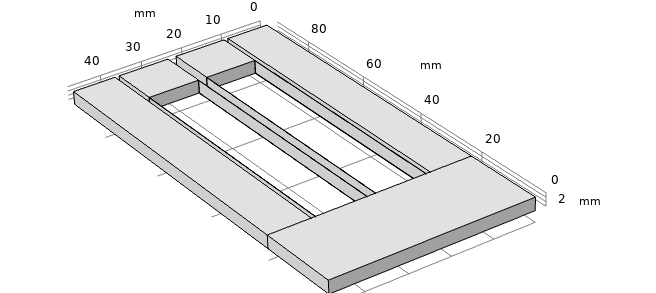

- When designing resonators, we need to predict the acceleration sensitivity to be achieved for a given topology and resonant frequency.

- This sensitivity is limited by readout noise and the self-noise of the resonator.

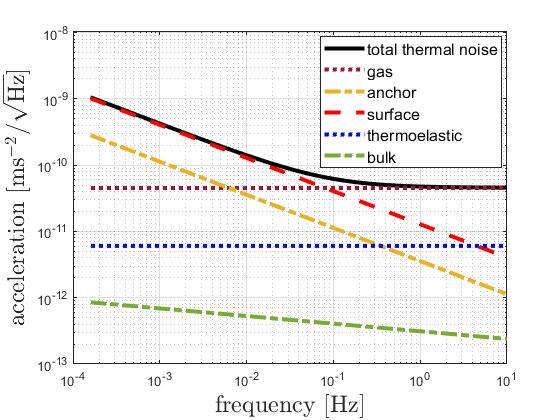

- The self-noise(sometimes called the thermal noise) represents the limiting sensitivity that can be achieved regardless of how good the readout is, and is highly dependent on the topology and material of the resonator.

- Therefore, through optimization of the resonator dimensions and careful selection of the material, self-noise is minimized.

- Thermal motion in the resonator is caused by the dissipation of elastic energy through numerous different mechanisms such as Lattice defects in the bulk of the material, damage on the surface of the resonator, bending due to spontaneous temperature fluctuations, air resistance, and acoustic coupling to the mounting equipment.

- Using models for these dissipation mechanisms, either found in literature or created in a finite element analysis software, we can predict the thermal noise of a given resonator and then optimize the geometry to lower this noise.

Researchers Involved:

Relevant Publications:

- Optomechanical inertial sensors, Appl. Opt. 59, G167-G174 (2020) – Adam Hines, Logan Richardson, Hayden Wisniewski, and Felipe Guzman