Making Telescope Mirrors

Overview: Making large telescope mirrors, called casting, is a very long and very precise operation. Taking the time to cast a mirror properly leads to clarity and resolution in telescopes that allow astronomers to accurately study the universe.

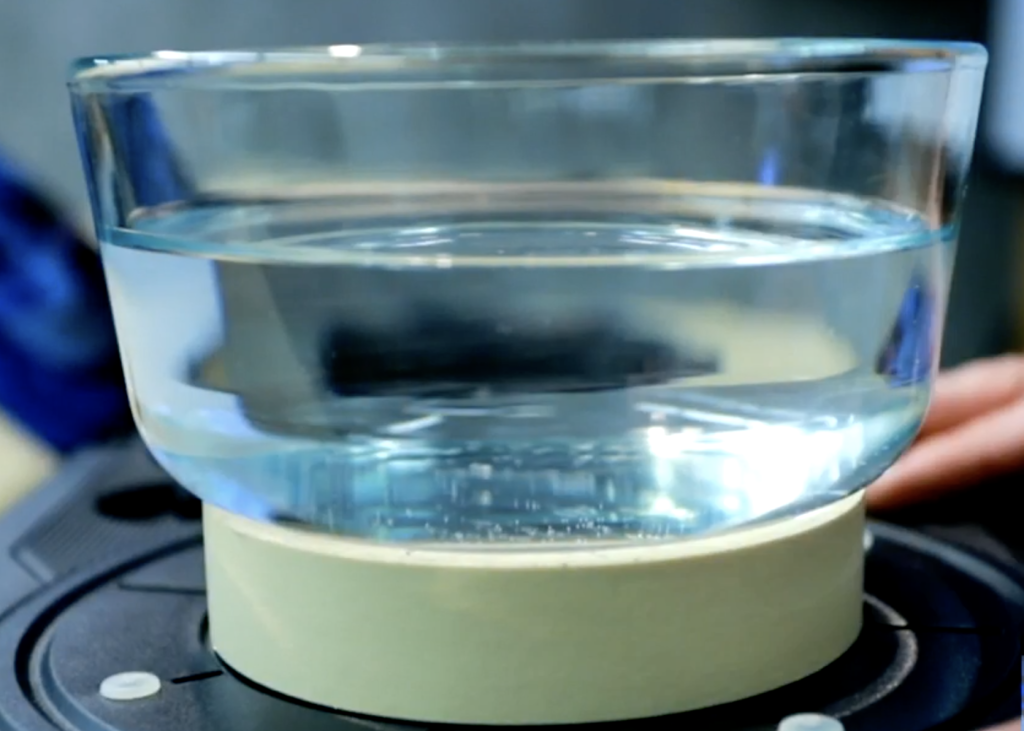

Supplies: Turntable, flat bottom dish, water

Objectives: Show how the rotational inertia of spinning a liquid can save mirror casters months of glass grinding by acquiring a rough initial mirror shape

Setup:

- Fill the dish half way up with water

- Place the dish in the center of the platform on the turn table

How to run the demo:

- Point out the level of the water in the dish

- Turn on the turn table

- Watch the level of the water on the walls of the dish increase as the level of the water in the middle of the dish decreases

What’s Happening?

Large parabolic mirrors are made by a process called spin casting. The spin cast process starts by placing large chunks of glass in a special round furnace. The furnace heats up and melts the glass into a liquid. The furnace starts spinning and centripetal force pushes the glass out into a parabolic shape. The furnace continues to spin, while slowly cooling down. This spinning and cooling process allows the glass to keeps its shape.

Learn more: (external links)