Projects

The OEFF has a long history of incredible and technologically-advanced enterprises. Use the link below to view our past projects.

Current Projects

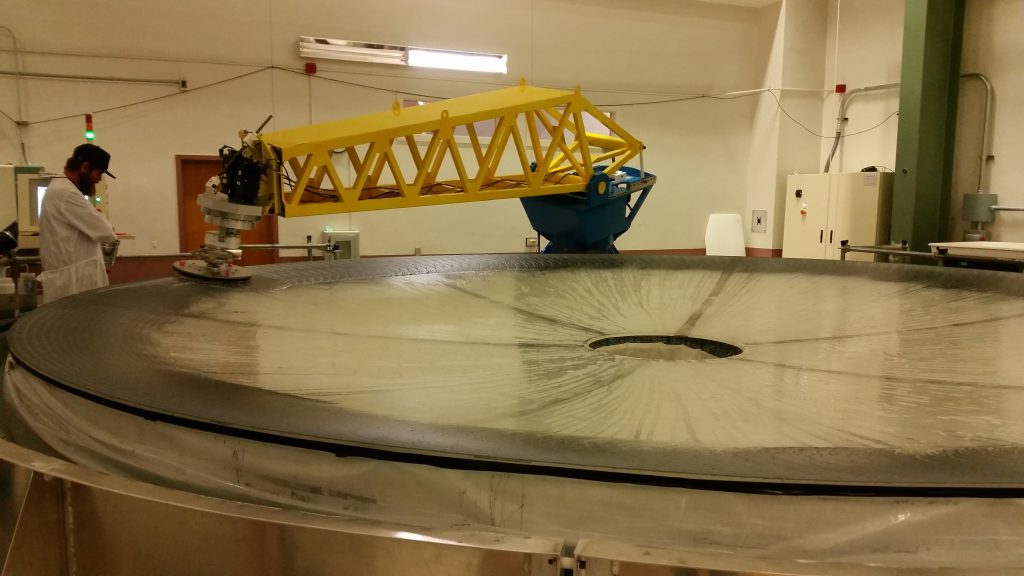

Tokyo Atacama Observatory 6.5m primary mirror system

The large optics shop is currently polishing the primary mirror for the Tokyo Atacama Observatory (TAO) which is to be located at the summit of Co. Chajnantor, 5,640 meter altitude, in northern Chile run by the Institute of Astronomy, University of Tokyo. The F/1.25 mirror blank is 6.5 meters in diameter with a Clear Aperture of greater than 6.461 meters. The Radius of Curvature is specified to be 16,256 +/- 2 mm with a conic constant K = -1.0040 +/- 1.0*10-4. The microroughness shall be smooth at spatial frequencies << 1 cm such that the microroughness shall not exceed 20 Angstroms rms. The mirror is currently undergoing acceptance testing.

UA SVPR facility capacity upgrade

The University of Arizona (UA) Senior Vice President for Research (SVPR) awarded the OEFF group the required funding to upgrade our 4.5 meter polishing system into a 6.5 meter polishing system. Previously, the OSC large optics shop was historically thought to be limited to mirrors approximately 4-meters in diameter due to the access hatch into the shop and capacity of the current machines. Our team developed a plan to upgrade the facility to make it possible to fabricate and test mirrors up to approximately 6.5 meters in diameter. This upgrade was started on 1/4/16 and finished on 5/1/17.

A few of the upgrades made to the facility are listed below:

Enlarged the Hatch for 6.5 meter mirror cell

Disassemble Bridge / Gantry and Stressed Lap System

New Polishing Machine Assembly

Upgraded Polishing Machine from 4.5 meter Gantry to 6.5 meter Swing Arm

Installed a new compressor system for testing

Redesigned Test Tower

Removed Fold Sphere from the previous project (DKIST)

Install new Metrology Mount hardware

Install new Polishing Cell and Mirror Support

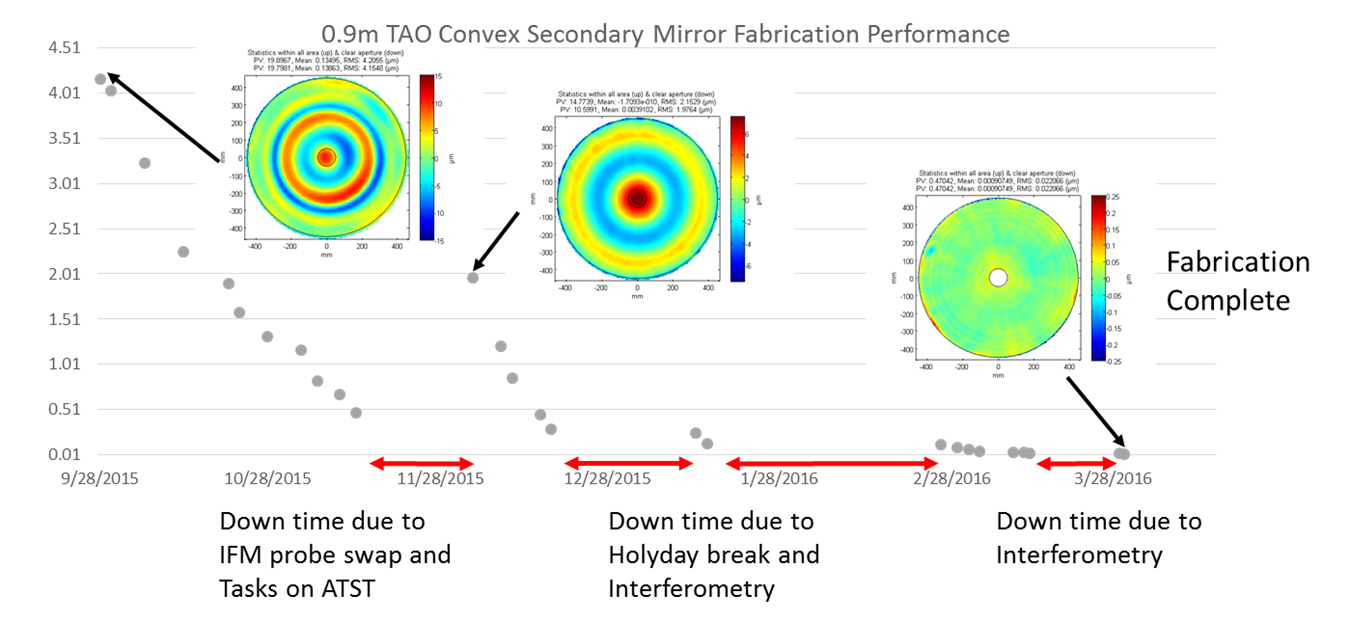

Tokyo Atacama Observatory 0.9m Convex secondary mirror system

The TAO 0.9 meter Convex secondary mirror was processed in 6 months from generated surface to finished product. There were significant amounts of down time due to a very complicated interferometry applied to the convex mirror. The actual rubbing time including swingarm profilometer measurement was about 3.5 months.

The Radius of Curvature was specified to be 2.657 meters.

The Surface Figure was measured to be less than 22.1 nm RMS over a 0.9 meter diameter.