Precision Metrology Lab

Purpose

The Optical Engineering Fabrication Facility (OEFF) Precision Metrology Lab’s purpose is to serve and support the College of Optical Sciences (OSC) research faculty, staff, and students in their research objectives. The lab is home to several state of the art metrology systems, optical alignment systems, and is a secure place to store equipment related to metrology. Potential clients benefit from the technology in this lab from the direct result of research engineers and students being able to measure and verify the optical performance of research experiments.

Fabrication Experiments

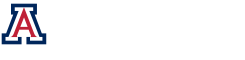

The OEFF Team has developed a new process yielding an Extreme finish for SiC of 0.6 nm RMS resulting in a Super Polished Surface! Using the Zygo NewView the measured area can range from 0.04 mm2 to 16 mm2.

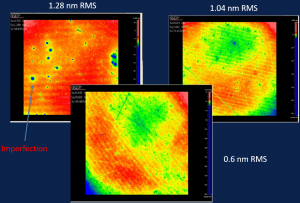

ZYGO NEWVIEW 8300 INTERFERENCE MICROSCOPE (OPTICAL SURFACE PROFILER)

FEATURES

The NewView™ 8000 series of 3D optical surface profilers provide powerful versatility in non-contact optical surface profiling. All measurements are nondestructive, fast, and require no sample preparation. Advanced software tools characterize and quantify surface roughness, step heights, critical dimensions, and other topographical features, with excellent precision and accuracy.

optical surface profilers provide powerful versatility in non-contact optical surface profiling. All measurements are nondestructive, fast, and require no sample preparation. Advanced software tools characterize and quantify surface roughness, step heights, critical dimensions, and other topographical features, with excellent precision and accuracy.

Profile heights can range from < 1 nm up to 20000 µm, at high speeds, independent of surface texture, magnification, or feature height!

Using ZYGO’s patented technology for Coherence Scanning Interferometry (CSI), the NewView 8000 series of profilers easily measure a wide range of surface types, including smooth, rough, flat, sloped, and stepped.

The NewView 8000 Series is offered in two configurations – a single zoom NewView 8200 configuration, and a triple zoom equipped NewView 8300 system. All NewView 8000 systems offer high-accuracy measurements, ease of use, and a wide variety of applications, all at an attractive price point that make it the ideal choice for versatility and value in 3D optical profilers.

ZYGO VERIFIRE™ INTERFEROMETER

FEATURES

ZYGO’s Verifire™ interferometer system provides fast high-precision measurements of plano or spherical surfaces, and transmitted wavefront of optical systems and assemblies. Measure glass or plastic optical components – like flats, lenses, and prisms – and even precision machined metal and ceramic surfaces.

A true laser Fizeau design, the Verifire™ system expands upon ZYGO’s unmatched experience in surface form metrology. The on-axis configuration combined with ZYGO’s patented acquisition algorithms and full-featured Mx™ metrology software enables high-precision surface form metrology with advanced analysis capabilities.

Alpha-Step D-600 Stylus Profiler

FEATURES

The Alpha-Step D-600 Stylus Profiler offers industry-leading high resolution 2D & 3D profiling, 2D stress, profile stitching and many additional features in an easy-to-use platform. The stylus profilometer system includes a 200 mm motorized stage, with 150 mm x 178 mm X-Y range of motion and an innovative optical lever sensor technology. The Alpha-Step D-600 Stylus Profiler also includes advanced optics and enhanced video controls for highly versatile sample visualization. The new sequencing software features manual deskew alignment, allowing users to program up to 1000 locations.

- Highest vertical range at 1200 μm

- Low force measurements at 0.03 to 15 mg

- Step height repeatability of 5 Å on a 1 μm step

- High resolution 5 MP color camera with 4x digital zoom

- New software features: Keystone correction, arc correction, sequencing with deskew, and automated stitching

- Intuitive user interface

Applications and Industries:

The D-600 Stylus Profiler has the capability to measure a wide range of applications in 2D and 3D, from nanometer to millimeter steps, high resolution roughness, soft materials, and thin film stress. This enables the D-600 Stylus Profiler to be the most versatile stylus profiler on the market—capable of serving various industries in research and development and production measurements.