Congratulations, Logan Graves (LOFT PhD student). Logan’s IR deflectometry poster presentation won the 2nd place at the Industrial Affiliates workshop, College of Optical Sciences, in Fall 2015.

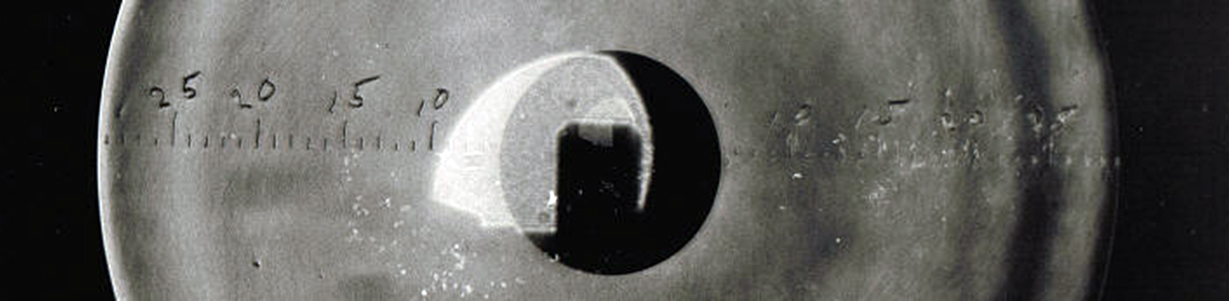

Check out the poster: IR Deflectometry Poster

Congratulations, Logan Graves (LOFT PhD student). Logan’s IR deflectometry poster presentation won the 2nd place at the Industrial Affiliates workshop, College of Optical Sciences, in Fall 2015.

Check out the poster: IR Deflectometry Poster

Speaker: Dr. Joohyung Lee

Korea Research Institute of Standard and Science (KRISS)

3:00 PM – Thu – June 20th – 2013

Conference Room 821

Femtosecond lasers offer unique characteristics in both the temporal and spectral terms, not observed in other continuous-wave or pulse lasers, permitting breakthroughs in precision dimensional metrology particularly. The temporal and spectral characteristics of femtosecond lasers were exploited in absolute distance measurement by means of pulse cross-correlation based interferometer and dual-comb interferometer which enable nanometer precision not only in laboratory environment but also in open-field. In this talk, absolute distance measurement technique will be described after brief introduction of femtosecond lasers and second half of the talk will be devoted to feasibility test of absolute optical testing exploiting distance measurement overcoming relative testing nature of conventional laser interferometer.

For more information, please contact Dae Wook Kim – dkim@optics.arizona.edu

Webinar at Photonics Media, http://photonics.com

Thursday, April 25, 1 pm ET/10 am PT

Dae Wook Kim will discuss various new approaches for advancing the current computer controlled optical surfacing process for manufacturing highly aspheric or free-form optics, such as 8.4-meter diameter Giant Magellan Telescope off-axis primary segment at the U of A. He will also present actual data demonstrating the performance of the enhanced process to build next generation optical systems.

Sponsored by: OPTIMAX

Optimax, a principal partner with the College of Optical Sciences (OSC) Industrial Affiliates program, is offering a $10,000 Optimax Product Grant for Research.

Title: Control of mid-spatial frequency errors

PI: Dae Wook Kim

Speaker: Dr. Wei-Yao Hsu, Researcher and division manager at Instrument Technology Research Center

Host: Dae Wook Kim (For more information, please contact via email.)

In this talk, I will give a brief introduction of Instrument Technology Research Center (ITRC) and the current development of precision optical fabrication at ITRC. ITRC is a government funded research institute pioneering in instrument related frontier researches in Taiwan. Currently, ITRC has four research fields ranged from electro-optics and remote sensing, nanotechnology and bio-medical, vacuum and thin-film technology, and instrumentation and auto-system engineering. Optical fabrication is one of the core technologies of the instrumentation and auto-system engineering field. ITRC devotes the fabrication technology of optical components, such as: lenses, mirrors, and prisms, to support the internal and external research requirements since it was founded in 1974. Based on the optical fabrication experiments, ITRC was supported to organize a large optics fabrication and inspection group to develop the large optics fabrication technology for remote sensing instrument since 2009. The first mission of this group is to deliver a 466mm concave mirror and a 160mm convex mirror in 2012. In this talk, I will also introduce what we have done for this mission.

Speaker: Dr. Benny Cheung, Professor and an Associate Head of the Partner State Key Laboratory of Ultra-precision Machining Technology in Department of Industrial and Systems Engineering at The Hong Kong Polytechnic University.

Host: Dae Wook Kim (Please, email me for more information.)

Topic: Research in Ultra-precision Machining and Freeform Surface Measurement

Abstract: The use of freeform optics for various industrial applications has become more widespread. In this presentation, the latest research related to Ultra-precision Machining and Freeform Surface Measurement being undertaken in the Partner State Key Laboratory of Ultraprecision Machining Technology at The Hong Kong Polytechnic University is presented. Some examples of applications of the technologies in freeform optics are also discussed.

Speaker: David Gritz, Director Sales, Heraeus Quartz America, LLC Optics Division

Host: Dae Wook Kim (Please, email me for more information.)

Title: Benefits of molding fused silica with a focus on cost savings of raw material and CNC machine time

David’s career has focused on new process, product and business development in glass (most notably in fused silica and fused quartz glasses) and glass-ceramics primarily focused in advanced optical products in the Photonics areas. Areas of expertise include advanced lasers, optical instrumentation, semiconductors optical metrology, microlithography, aerospace optics, astronomy, optics used in military and scientific R&D. Over the past 20 years, David has managed the development of over 30 new technology enabling products used by many tier-one manufacturers in these fields and has been responsible for development new business exceeding $100M’s business for Corning, Lucent & Heraeus.

Edmund Optics wrote a press release to herald the recently published SPIE “Field Guide to Optomechanical Design and Analysis,” which was written by professor James H. Burge and alumna Katie Schwertz.

Since LOFT group released the beta version SAGUARO in Sept. 20011, the first official release of SAGUARO 1.4 is now available. Many thanks to the LOFT SAGUARO team.